After 13 years and a last inspection of the pistons and bores it was time to fit the cylinder head of the B20B engine. First I fitted the new water pump. The pump came with two sets of rubber rings: 1 set with a height of 8.5 mm and the other one with a height of 9.5 mm. The 8.5 mm rings are for the B20B engine which has a thinner head gasket than the B18 engine.

I lubricated the new tappets inside and out with assembly oil and put them into the bores. Be careful not to drop them in the sump...

|

| New tappets and original pushrods |

|

| Tappets fitted in their bores |

After the bores and pistons were also lubricated with an overdose of oil the gasket was alined with the bolt holes and the cylinder head was placed on top of it.

|

| Cylinder head gasket alined with bolt holes |

|

| Make sure the word "TOP" is on top :-) |

Before that I cleaned and checked all the cylinder bolt holes just by putting in the bolts and made sure they went in all the way.

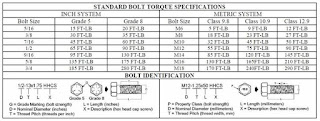

The cylinder head bolts have to be tightened in a special sequence to the first torque of 39.5 Nm. There will be two more stages of thightening...

|

| Old - and new cylinder head bolt |

|

| Tightening sequence of cylinder head bolts |

Next thing to do is fitting the pushrods on top of the tappets. The rocker shaft and arms were already assembled so after good lubrication of the shaft I fitted it to the head with a torque of 33.5 Nm.

After refitting the rocker arm assembly for the second time the valve clearances have to be adjusted. The valve clearance is the gap between the cam/pushrod and the top of the valve. For a Volvo B20B engine the clearance is 0.50 - 0.55 mm (both inlet - and outlet valves).

Cylinder 1 in TDC --> adjust cylinder 4 valves

Cylinder 2 in TDC --> adjust cylinder 3 valves

Cylinder 3 in TDC --> adjust cylinder 2 valves

Cylinder 4 in TDC --> adjust cylinder 1 valves

* TDC = Top Dead Centre - the point that both valves are completely closed

|

| Valve clearance adjustment |

|

| Rocker cover fitted |